Living beer

Gulden Draak has been brewed honouring the traditional use of precious hop varieties and unique strains of yeast since 1986. Our brewers control the high fermentation, natural lagering and re-fermentation processes with skilful mastery.

Gulden Draak is living beer with a unique, extended flavour evolution.

The brewing process consists of several phases. Every one of these phases demands continuous attention to quality and a passion for the beer.

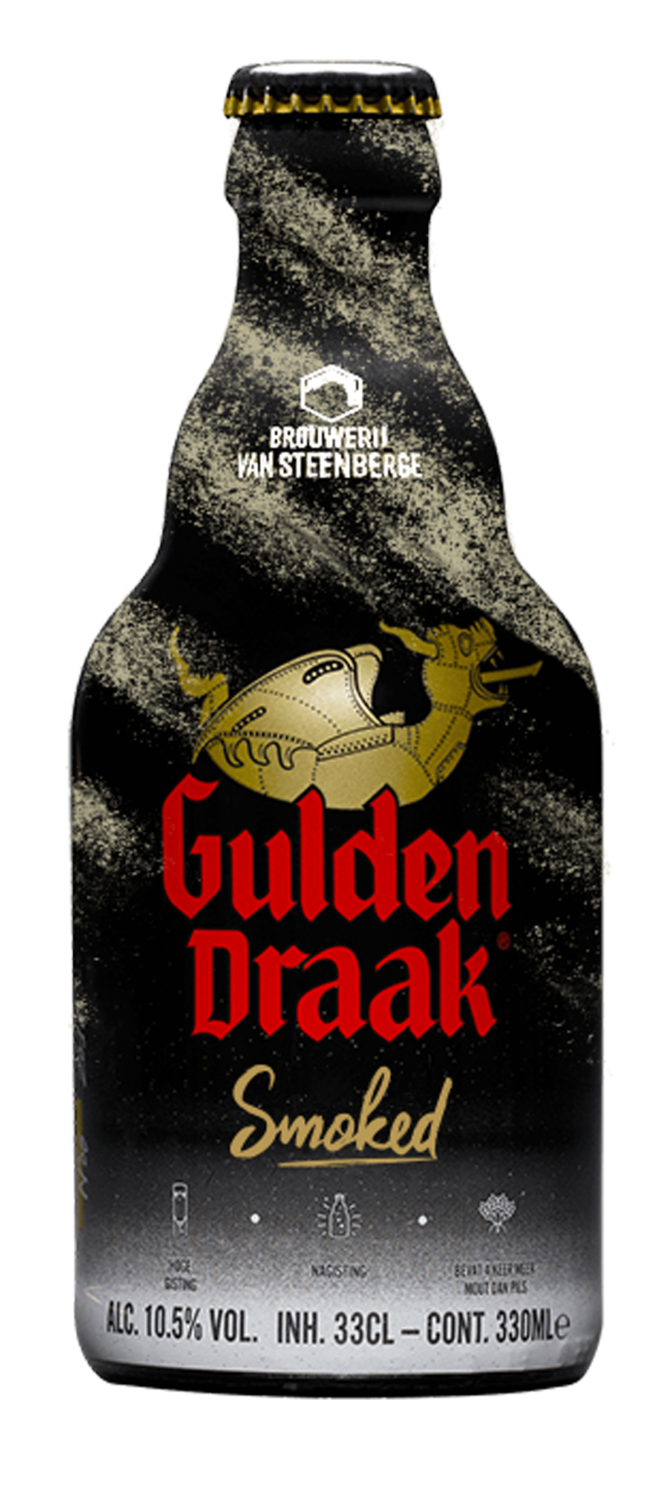

Gulden Draak Smoked

Dark, heavy smoked beer

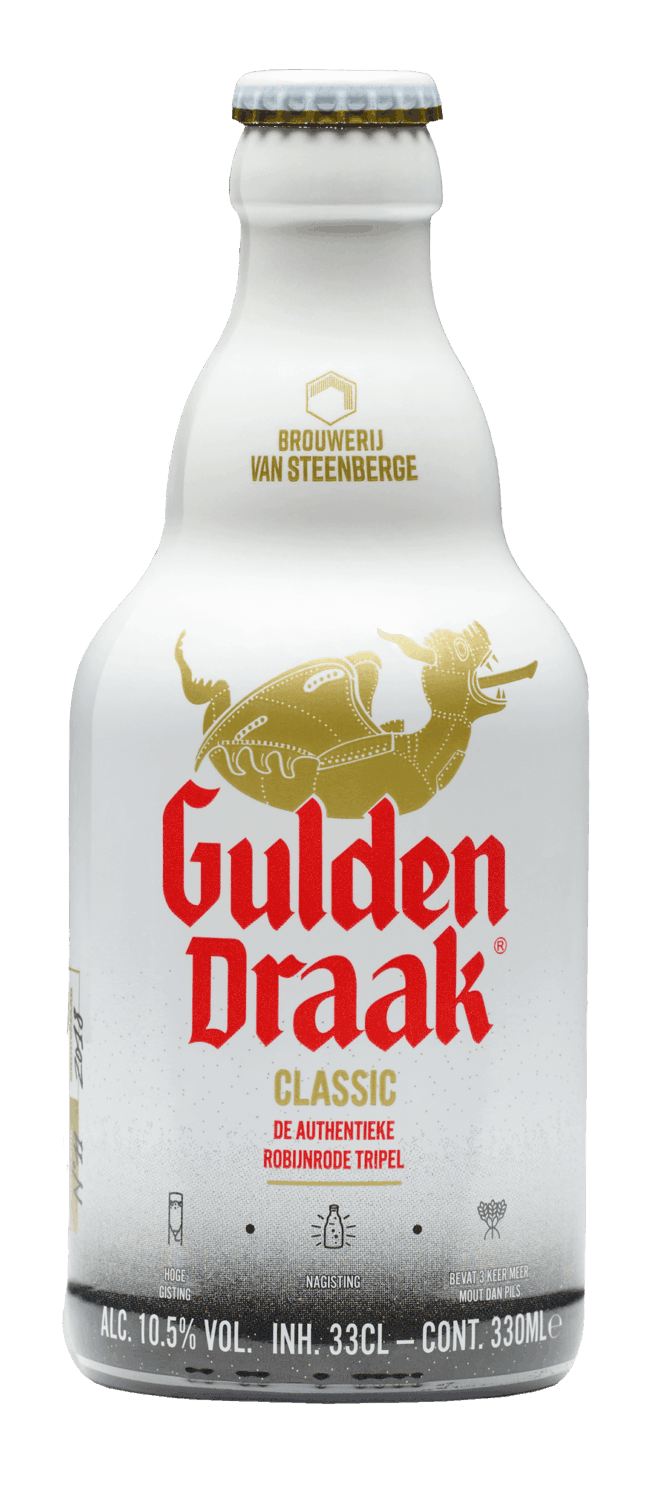

Gulden Draak Classic

The authentic, dark red tripel.

Gulden Draak 9000 Quadruple

An exceptional quadruple amber.

Gulden Draak Brewmaster

An ode to six generations of master brewers.

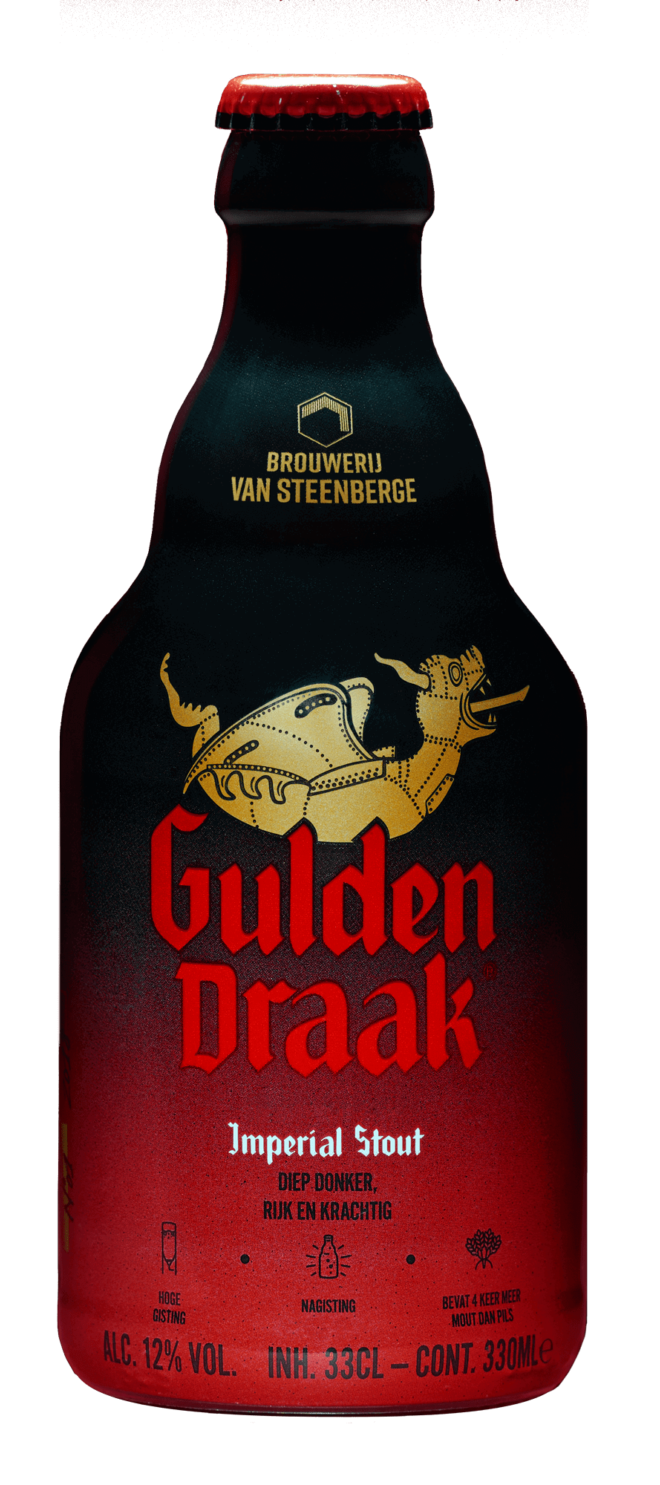

Gulden Draak Imperial Stout

Deep dark, rich and powerful.

THE BREWING ROOM

The first step in the brewing process is the formation of sugar water. This takes place in the fully automatic brewing room. Gulden Draak is a specific type of specialty beer called a ‘tripel’. This name refers to the fact that the brewer uses three times as much malt for this beer as for a lager. The wort formed here is then sterilised by boiling.

During this boiling process, hops, a necessary ingredient for the natural preservation of this special beer, are added. And finally, the wort is cooled and sent to the fermentation room.

HIGH FERMENTATION

The Van Steenberge Brewery has mastered the process of high fermentation like no other brewery. This fermentation occurs at the top of the various fermentation tanks in the tank cellar. For this process, we use yeast strains that we have cultivated ourselves for years now, right here in the brewery. This quality is unique to our beer – the ‘propagation’, or in-house cultivation of this yeast culture, distinguishes our brewery from many others. The fermentation process takes twelve days, on average, after which time the yeast will be broken down naturally. The expertise and skill of the brewery guarantees the quality of the beer, even at different volumes.

Lagering

The prime fermentation is then interrupted naturally by the lagering process. Lagering is the process of cooling the beer down to a temperature of 0° Celsius; this process takes a minimum of 16 days to complete.

FILTRATION

After the lagering period, the beer is filtered to remove any yeast residue from the beer. After filtering, the Gulden Draak ends up in the ‘clear beer’ tank'. It is from this tank that the beer heads for the bottling process.

BOTTLING

Gulden Draak is bottled in 33cl, 75cl, 1.5l or 3l bottles. During bottling, the brewers add a unique variety of wine yeast and sugars to the beer. These additions will initiate the re-fermentation process.

RE-FERMENTATION

Finally, the bottled beer is placed in the warm chambers for two weeks. The re-fermentation process is activated here, due to the warm temperatures. The added yeast converts the sugar into alcohol and carbon dioxide, while releasing delicious aromas – exactly what is needed to make Gulden Draak a living beer. The older the beer gets, the more aromatic it becomes and the fuller the flavour and the colour that develop.

After fifteen days, most of the sugars have fermented, and the beer is ready for consumption.